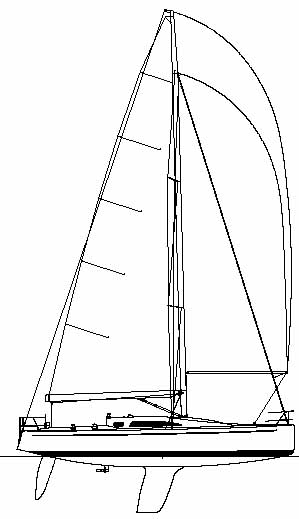

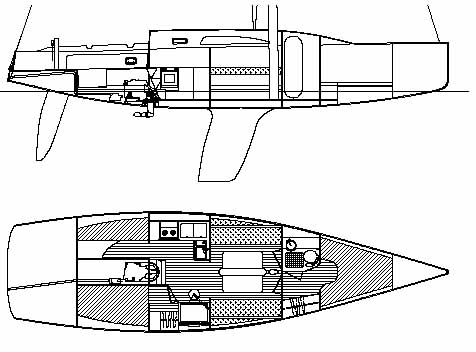

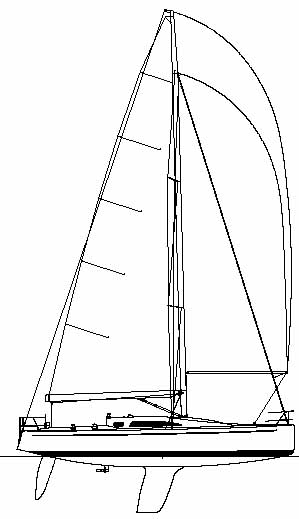

The yacht is built by new project of world leader in yacht design – Farr Yacht Design Ltd USA. The yacht fully corresponds to IMS 600 standard in racing/cruising division and is certified by ORC club. The yacht is built by new project of world leader in yacht design – Farr Yacht Design Ltd USA. The yacht fully corresponds to IMS 600 standard in racing/cruising division and is certified by ORC club. The yacht is built from composite materials and in accordance with  technologies developed by High Modulus Ltd, New Zealand. High Modulus Ltd implements full integration with components for the given project and it also provides engineering and technological control of composite production. technologies developed by High Modulus Ltd, New Zealand. High Modulus Ltd implements full integration with components for the given project and it also provides engineering and technological control of composite production.

Our shipyard conducted training of engineers and production technologists on the base of a whole series of New Zealand yacht-building yards with participation of composite resin manufacturers: Chemical Specialties, NZ (West System). Technical literature was presented by Boating Industry Training Organisation (NZ), Adhesive Technologies Ltd, High Modulus Ltd.

The use of “preimpregnated” technology and equipment (resin  impregnator – is a machine for preliminary wetting of fabric with epoxy resin for subsequent lay up) during hull construction allows to get accurate resin and glass fabric ratio in epoxy composite impregnator – is a machine for preliminary wetting of fabric with epoxy resin for subsequent lay up) during hull construction allows to get accurate resin and glass fabric ratio in epoxy composite  that gives necessary parameters of main composites – tension, compression, bending and deformation. Vinylester layer in sandwich outer coating guarantees anti-corrosion protection of the construction under any influences of surrounding environment. At the same time it provides full adhesion on the transfer of polyester gelcoats (finish protecting layer) to the main supporting layers of epoxy resins. Full impregnation of sandwich balsa core under vacuum with epoxy resins with addition of aerosol guarantees sandwich adhesion and its increased bearing capacity. that gives necessary parameters of main composites – tension, compression, bending and deformation. Vinylester layer in sandwich outer coating guarantees anti-corrosion protection of the construction under any influences of surrounding environment. At the same time it provides full adhesion on the transfer of polyester gelcoats (finish protecting layer) to the main supporting layers of epoxy resins. Full impregnation of sandwich balsa core under vacuum with epoxy resins with addition of aerosol guarantees sandwich adhesion and its increased bearing capacity.

The best materials application in sandwich yacht construction in compliance with technological process of vacuum bagging and thermal treatment (within IMS rules) recommended by composite producers for the given project guarantees durability, strength, lightness and conformity with high international standards.

The yacht is equipped with Harken, Great Britain. This can be modified on customer’s request. Yacht interior is made in accordance with customer’s demands. Supplier of carbon masts, running and standing rigging for the project is Formula Yacht Spars Ltd.Formula Yacht Spars Ltd. specializes in manufacturing of carbon masts and spars for cruiser yachts and it is a leader in carbon masts production for Farr projects in Europe. Rigging is integrated according to customer’s demands.

The project is approved and supervised by All-Russian Yacht Racing Federation. All-Russian Yacht Racing Federation conducts a series of interesting programs. It organizes large competitions such as The Cup of President, Championships of Russian Federation, Regatta of CIS and others. The preparation is being done for holding in 2006 and 2007 World and European Championships in class SkiF-42 involving countries of Azov and Black sea regions. The project is approved and supervised by All-Russian Yacht Racing Federation. All-Russian Yacht Racing Federation conducts a series of interesting programs. It organizes large competitions such as The Cup of President, Championships of Russian Federation, Regatta of CIS and others. The preparation is being done for holding in 2006 and 2007 World and European Championships in class SkiF-42 involving countries of Azov and Black sea regions.

The project is approved and supervised by All-Russian Yacht Racing Federation.

|

Shipyard

Shipyard Our team

Our team  Competitions

Competitions  Contacts

Contacts

The yacht is built by new project of world leader in yacht design –

The yacht is built by new project of world leader in yacht design –  technologies developed by

technologies developed by  impregnator – is a machine for preliminary wetting of fabric with epoxy resin for subsequent lay up) during hull construction allows to get accurate resin and glass fabric ratio in epoxy composite

impregnator – is a machine for preliminary wetting of fabric with epoxy resin for subsequent lay up) during hull construction allows to get accurate resin and glass fabric ratio in epoxy composite  that gives necessary parameters of main composites – tension, compression, bending and deformation. Vinylester layer in sandwich outer coating guarantees anti-corrosion protection of the construction under any influences of surrounding environment. At the same time it provides full adhesion on the transfer of polyester gelcoats (finish protecting layer) to the main supporting layers of epoxy resins. Full impregnation of sandwich balsa core under vacuum with epoxy resins with addition of aerosol guarantees sandwich adhesion and its increased bearing capacity.

that gives necessary parameters of main composites – tension, compression, bending and deformation. Vinylester layer in sandwich outer coating guarantees anti-corrosion protection of the construction under any influences of surrounding environment. At the same time it provides full adhesion on the transfer of polyester gelcoats (finish protecting layer) to the main supporting layers of epoxy resins. Full impregnation of sandwich balsa core under vacuum with epoxy resins with addition of aerosol guarantees sandwich adhesion and its increased bearing capacity. The project is approved and supervised by All-Russian Yacht Racing Federation. All-Russian Yacht Racing Federation conducts a series of interesting programs. It organizes large competitions such as The Cup of President, Championships of Russian Federation, Regatta of CIS and others. The preparation is being done for holding in 2006 and 2007 World and European Championships in class SkiF-42 involving countries of Azov and

The project is approved and supervised by All-Russian Yacht Racing Federation. All-Russian Yacht Racing Federation conducts a series of interesting programs. It organizes large competitions such as The Cup of President, Championships of Russian Federation, Regatta of CIS and others. The preparation is being done for holding in 2006 and 2007 World and European Championships in class SkiF-42 involving countries of Azov and